© Copyright – 2010-2023 : All Rights Reserved. Sitemap

Power Distribution Unit PDU, rack mount PDU, PDU data center, Smart PDu, intelligent PDU

Power Distribution Unit PDU, rack mount PDU, PDU data center, Smart PDu, intelligent PDU

DTI-CX 2025 Digital Transformation Indonesia Conference, DATE:6-7 AUG.2025, Booth No.: C21

Power problems cause more than half of big data center outages, says the Uptime Institute’s latest reports. Operators use advanced PDU solutions to make systems more reliable and keep them running longer. Intelligent PDUs help with real-time monitoring, automation, and saving energy. This means lower costs and better performance. The table below shows how good PDU power management brings clear improvements:

Aspect | Benefit |

|---|---|

Energy Efficiency | Uses up to 20% less energy |

Downtime Reduction | Has 30% fewer downtime incidents |

Automation | Needs less manual work and has more uptime |

YOSUN’s High Power PDU fits today’s needs, and a pdu power calculator helps operators get ready for future growth.

Intelligent PDUs show power use right away and can be controlled from far away. This helps data centers stop power loss and save energy.

Picking the best PDU and using outlet control makes power use better. It also stops too much power from being used at once.

Remote access and automation tools help workers fix problems fast. They can also manage power well from any place.

Doing regular checks and updating firmware keeps PDUs safe and working well. This also helps them get ready for new needs.

Custom PDUs like YOSUN’s High Power models help data centers grow. They balance power and keep equipment safe in many places.

Power Distribution Units, or PDUs, come in different types. Each type is made for a certain job in a data center. Operators pick a PDU by looking at the center’s size and equipment. They also think about how much control they need. The table below shows the main PDU types, what they do, and where they work best:

PDU Type | Features & Functionality | Ideal For |

|---|---|---|

Basic | Simple power distribution, no monitoring or remote control | Small data centers, non-critical setups |

Metered | Real-time power usage data via local display | On-site monitoring in growing centers |

Monitored | Remote monitoring, historical data, alerts | Medium to large centers needing proactive management |

Switched | Remote outlet-level control, monitoring | Centers with dynamic workloads |

Managed/Smart | Advanced metrics, remote management, environmental sensors, DCIM integration | Large, complex data centers |

Tip: Picking the right PDU type helps operators save money. It also gives them the control and reliability they need in any data center.

PDUs are very important in every data center. They send power from the main source to servers and other IT gear. This keeps the power steady and safe. Operators use PDUs to watch power use and stop overloads. They can also manage things from far away. Intelligent PDUs have special features like checking each outlet and sensing the environment. These features help find problems early and plan for more equipment. PDUs work with backup systems like UPS units. This makes the center more reliable and saves energy. PDUs follow rules like UL, CE, and RoHS to keep power safe. In modern centers, PDUs are the last step in the power chain. They give clean power and help important systems run. PDUs can record events, send alerts, and balance loads. This helps operators stop outages and keep everything working well.

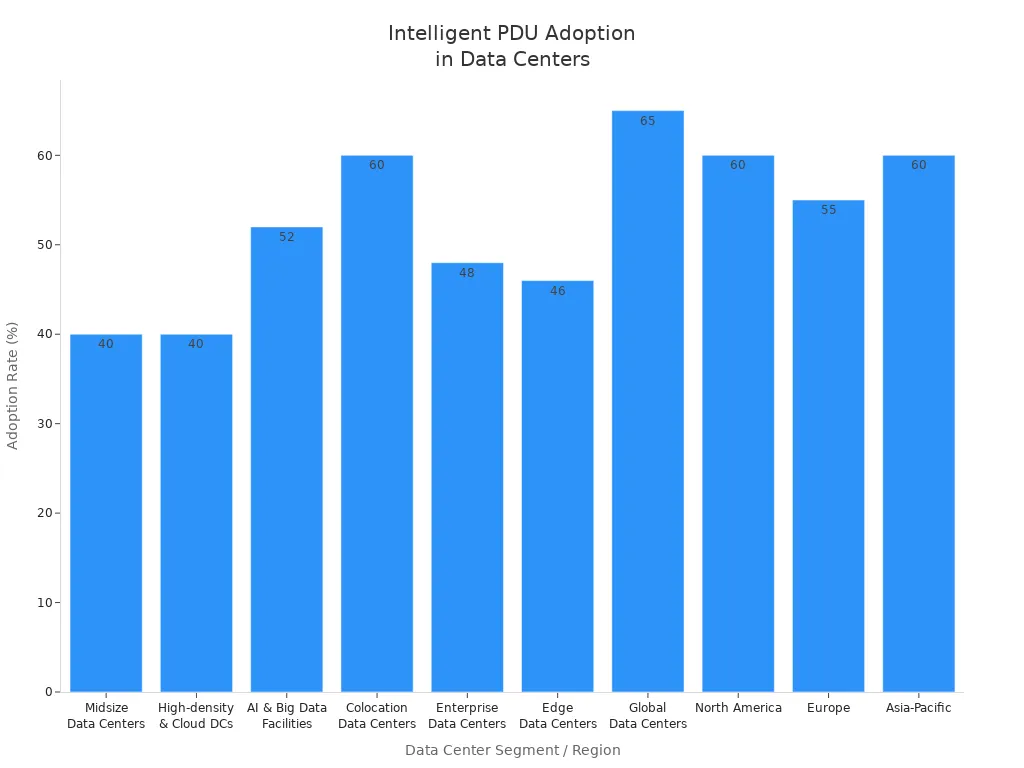

Intelligent PDUs are very important in today’s data centers. Operators use these devices for more than just power. They want smart pdus to give them control and help save energy. These PDUs are now used in many places and types of data centers.

Advanced monitoring is a main part of intelligent PDU technology. Operators use these features to watch power and the environment all the time. Smart pdus connect to networks, so people can check them online. They measure things like voltage, current, and energy at different spots. This information helps operators use energy better and plan for more equipment.

Some important features of intelligent PDUs are:

Network connections for remote checking and control

Meters that show detailed power numbers

DCIM integration for easy reporting

Sensors for temperature, humidity, and airflow

IP address grouping for simple network setup

Strong security with good passwords and encryption

Operators get real-time updates, so they can fix problems fast. Sensors warn staff if it gets too hot or wet. The table below shows how advanced monitoring helps data centers work better:

Feature | Benefit |

|---|---|

Real-time Monitoring | Helps save energy and work more efficiently |

Remote Management | Cuts downtime with easy control |

Environmental Sensors | Stops failures by watching temperature and humidity |

Customization & Scalability | Makes it easy to grow and stay green |

Note: Smart pdus with advanced monitoring help operators use less energy and stop expensive outages.

Outlet-level control lets operators manage each device by itself. Smart pdus can switch outlets from far away, so staff do not need to go to the rack. This makes fixing problems faster and keeps downtime low.

Outlet-level control gives these benefits:

Reboot equipment from far away to keep things running

Turn outlets on or off without being there

Set power schedules to save energy

See power use at each outlet for better balance

Stop overloads by setting limits for each outlet

Switched smart pdus give even more control, so they are great for big or far-away data centers. Operators can fix issues quickly, keep things working, and use energy wisely. Watching each outlet also helps plan ahead and stop overloads before they happen.

Tip: Outlet-level control in smart pdus helps keep data centers working well and saves energy.

Remote access is very important for PDU management today. Operators use it to control power outlets from far away. They can also check energy use and fix problems fast. They do not need to be at the data center. This helps stop downtime and makes work easier. Most advanced PDUs have many features for remote management:

Switch and restart power outlets from a distance

Watch power use and balance loads in real time

Use sensors to check temperature, humidity, and airflow

Use safe network tools like SNMP, SSH, and web pages

Connect with DCIM platforms for alerts and easy checks

Link PDUs together to make network management simple

Use security like encryption and strong passwords

These features are great for remote or edge data centers. Sometimes, there are no IT staff on site. Operators get alerts if there are power or environment problems. This lets them fix things before they get worse. Remote monitoring helps teams watch everything from anywhere. This keeps the business running well.

Tip: Remote access features help data centers stay online and need fewer visits from staff.

Automation tools change how operators handle power in big data centers. Smart and switched PDUs show power use at each outlet. They also give real-time updates. This helps teams see problems early and stop overloads. Operators can set up and manage PDUs from far away. This saves time and energy.

Automation tools work with other systems using APIs and network rules. This makes it easy to connect with building and DCIM systems. It also helps with automatic control and planning for the future. Sensors check voltage, frequency, and power quality. They can switch things or send alerts if something is wrong.

Automation lets racks hold more equipment and saves space

Real-time data helps with green goals and following rules

Automated steps mean less manual work and faster fixes

Operators get better uptime and fewer surprise outages. They also work more efficiently. Automation tools help keep important systems running and meet new data center needs.

Data centers need strong power systems to keep things working. Operators use different steps to balance power and stop overloads. Modern rack PDUs send the right amount of power to each server. This helps keep energy use even and stops hot spots that can break equipment.

Operators follow these steps for load balancing:

Use rack PDUs to give power straight to each IT device.

Pick PDUs that let you watch and control power from far away.

Look at real-time power data at each rack to help balance loads.

Use power cycling in PDUs to control devices and save energy.

Choose advanced PDUs that help plan for more equipment and balance loads.

Add surge protection in PDUs to keep devices safe.

These steps help operators find problems early and change power use fast. Real-time data helps teams act quickly, so the data center stays safe and works well.

Tip: Using the right power steps helps stop downtime and lets the center grow.

Redundant design is very important for keeping data centers running. Operators use different ways to make sure power stays on if one source fails. Redundant PDUs often have two power inputs and automatic transfer switching (ATS). This lets the system switch power sources without stopping devices.

Two power inputs and ATS switch power if one fails, so power stays on.

Two PDUs in each rack give backup power, lowering the chance of outages.

ATS lets single-corded devices use two power sources, making things safer.

Remote management lets operators watch power and fix problems fast.

Redundant PDUs balance power loads and help save energy and cooling costs.

This design gives steady power and keeps important systems working.

Operators trust these designs to keep data centers running during problems. Redundant PDUs help everyone feel safe and keep service levels high.

Modern data centers need to watch the environment closely. Intelligent PDUs have sensors for temperature and humidity. These sensors give real-time data to operators. Operators use this data to keep the temperature between 64° and 81°F. They also keep humidity between 40% and 60%. Sensors are put in server racks and air vents. This helps operators find changes early. It stops overheating, condensation, and static electricity. These problems can hurt important equipment.

PDUs have alert systems for safety. They warn when temperature or humidity is not safe. Operators act fast when they get alerts. This lowers the chance of equipment breaking or power going out. Watching the environment also saves energy. Teams do not cool too much and use airflow better. By managing air flow and airflow, operators keep things running well and protect equipment.

Note: Good air flow management and watching airflow help stop hot spots and keep things working right.

Data analytics help make PDU performance and energy use better. Advanced PDUs collect real-time data on power, temperature, humidity, and airflow. Operators use this data to find problems and balance power in racks. Analytics let operators make small changes to improve uptime and save energy.

Operators use predictive maintenance to get early warnings. This helps equipment last longer. Old data helps teams plan for busy times and use resources well. Central software brings all the data together for better control and analytics. This makes air flow management work better.

Aspect | Explanation |

|---|---|

Real-time Monitoring | See power, temperature, humidity, and airflow data right away. |

Predictive Maintenance | Early warnings help stop downtime and keep equipment working. |

Energy Savings | Analytics can cut energy costs by up to 30%. |

Load Balancing | Smart power use stops overloads and saves energy. |

Capacity Planning | Old data and models help teams plan for the future. |

Integration with Software | Central platforms bring data together for easy control. |

Outlet-level Control | Managing outlets well keeps things reliable and saves energy. |

Environmental Monitoring | Sensors watch temperature, humidity, and airflow to stop problems. |

Firmware Updates | Analytics help update systems for better performance. |

Operators use air flow management and analytics to keep the best conditions. This stops failures and saves energy. These steps help data centers work well and protect equipment.

Teams need to check PDUs often to keep them working well. They should follow a plan to stop problems and help equipment last longer. Experts say there are some important steps:

Do preventive maintenance a few times each year. This helps find problems before they cause downtime.

Use OEM checklists for every maintenance visit. These lists help teams do all the right tasks and not miss anything.

Run load bank tests to see if PDUs can handle different power needs. This checks if they work well in real situations.

Look at PDUs every month to find early signs of damage or wear. Finding problems early means repairs can happen fast and outages are less likely.

Make sure loads are balanced. Balanced loads stop overheating and help equipment last longer.

Teach staff how to fix small problems. Teams who know what to do can fix things fast and make fewer mistakes.

Clean and check PDUs often to get rid of dust and stop overheating.

Use cable organizers and strain relief tools to keep connections safe from pulling or bending.

Tip: Smart PDUs with real-time monitoring let teams see power use and find problems fast.

Firmware updates are very important for keeping intelligent PDUs safe and working well. These updates add new security, fix bugs, and bring new features. For example, updates can give stronger encryption, better password rules, and safer ways to log in. Teams might also get new tools like AutoPing Recovery, more IPv6 support, and easier outlet control.

Doing firmware updates often helps PDUs keep up with changes in the data center. Updates can make the user interface better, add support for new devices, and make it easier to manage everything. They also fix problems with event logs, network links, and system stability. Keeping firmware up to date lowers the chance of security problems and helps things run smoothly.

Note: Planning regular firmware updates keeps PDUs safe, reliable, and ready for new needs.

YOSUN’s High Power PDU is special because it meets the needs of modern data centers. The YOSUN team works with customers to design PDUs that fit their needs. This makes sure each unit gives steady power and can handle changes.

Operators can pick from many customization choices. These include how the PDU is installed, what outlets it has, input power types, and smart management features. YOSUN lets you choose horizontal or vertical mounting, so PDUs fit in different racks. The company offers many outlet types, like IEC 60320 C13, C19, C15, C21, Schuko, and NEMA. This helps support many kinds of equipment. Input power options include NEMA L5-30P, L6-30P, and IEC 60309. Both single-phase and three-phase power are supported.

The table below shows important customization choices and options:

Customization Aspect | Options / Details |

|---|---|

Mounting Orientation | Horizontal (1U-2U rack space), Vertical (back/side rack mount, up to 40 outlets) |

Outlet Types & Quantities | IEC 60320 C13, C19, C15, C21, Schuko, NEMA |

Input Power Connections | NEMA L5-30P, L6-30P, IEC 60309 (single-phase or three-phase power) |

Intelligent Features | Remote monitoring, alerts/notifications, energy management, load balancing |

Certification | UL and VDE safety certifications for outlets |

OEM/ODM Services | Custom designs for specific customer needs, ensuring compatibility and scalability |

YOSUN’s modular design lets operators change power setups without stopping work. This means data centers can grow and use new tech easily. Customization helps match power to each rack or tenant, making things work better.

Operators get smart features like real-time monitoring, remote control, and sensors for the environment. These tools help teams use less energy, balance loads, and fix problems fast. YOSUN’s focus on customization means every data center gets a solution made for safety, reliability, and long-term use.

Tip: Customization from YOSUN helps data centers be more reliable and ready for the future.

YOSUN High Power PDUs make data centers work better and more reliably in tough places. The strong build, aluminum shell, and overload protection make them good for busy racks and important jobs.

Operators use YOSUN’s three-phase PDUs to balance power and stop overloads. This saves energy and lowers cooling bills. The smart monitoring lets teams watch power use and spot problems fast. These features help keep power steady and the center running well.

YOSUN High Power PDUs are great for these uses:

High-Density Data Centers: Modular design makes it easy to add or move power as server numbers grow.

AI and HPC Workloads: These jobs need strong, steady power. YOSUN’s PDUs give safe power for big computing tasks.

Cryptocurrency Mining Operations: Mining groups see up to 30% better energy use with YOSUN’s smart PDUs. Custom alerts help stop downtime and let them grow.

High-Frequency Trading Firms: These firms need fast, steady power. YOSUN’s PDUs keep things running and protect gear.

Industrial Facilities and Edge Computing: Flexible and remote features help operators use power well and keep things working in many places.

Operators also get lots of outlets, locking sockets, and safety certifications. These features stop unplugging by accident and protect equipment from power problems. Real-world use shows less downtime and lower energy costs.

Note: YOSUN High Power PDUs help data centers stay efficient and reliable, even when power needs change quickly.

Unified control systems help teams manage many PDUs at once. These systems give one place to watch and control power. Teams can turn outlets on or off from far away. They can also restart devices without going to the data center. This makes fixing things faster and safer. Repairs can be up to 40% quicker. Teams can balance loads and see how much power is used. This helps save energy and plan for more equipment.

Operators get these benefits with unified control:

Watch and control PDUs in real time from one spot

Turn outlets on or off quickly for fixes or emergencies

Balance loads better and use up to 20% less energy

Track power use to plan for more equipment

Keep things safe with surge protection and circuit breakers

Grow the center and still manage power well

Use sensors to check temperature and humidity

Need fewer workers at the site, which saves money

Use Automatic Transfer Switch PDUs for better uptime

Get alerts if something is wrong, so problems get fixed fast

Intelligent PDUs are a big part of unified control. They let teams manage each outlet from anywhere. This makes power management more reliable and gives teams more control.

Centralized software puts all PDUs on one platform. Teams use this software to watch and control power everywhere. The software works with PDUs from different brands. Teams do not worry about mixing brands. Real-time data shows how much power is used and if things are working well. Teams can act fast to keep things running.

Here are ways centralized software helps manage power:

Control all PDUs from one place, even if they are different brands.

See real-time power use and health for quick choices.

Mix PDUs from many brands with no trouble.

Make power management easier and do less manual work.

Grow the center easily as needs change.

Save money by using fewer tools and less energy.

Watch things better to keep the center running.

Update firmware to keep systems safe and strong.

Feature/Capability | Description and Benefit |

|---|---|

Unified Interface | Watch many PDUs, even from different brands, on one platform. |

Customizable Health Maps | See cabinet health quickly to keep things running and plan for more. |

Enhanced SNMP Protocol | Get alerts with proof they were sent, even if the network is down. |

Accurate Data Sampling | Get real-time meter readings for good tracking and billing. |

On-Demand Billback Reports | Track energy costs by customer or group for clear bills. |

Data Buffering | Save up to two hours of data so nothing is lost if the network goes out. |

Firmware Update Management | Update firmware easily to keep systems safe and working well. |

Centralized software helps teams keep the center safe and working well. Teams use it to plan, watch, and fix things fast. This makes power management strong and ready for the future.

A pdu power calculator helps operators pick the right power setup. They use it to match power needs for servers and network gear. First, they check the highest kilowatt demand for all IT devices. This makes sure the PDU can handle busy times. Operators also look at power for cooling and backup systems. They use Power Usage Effectiveness (PUE) to see how well energy is used. A lower PUE means the center uses less energy. The calculator looks at rack size, server density, and cooling needs. This stops overheating and keeps equipment safe.

Key things to think about when using a pdu power calculator are:

Checking IT load and peak demand for all equipment

Adding power for cooling and backup systems

Using PUE to watch energy use

Planning for space, density, and airflow

Picking modular designs for easy upgrades

Making layouts better for airflow and cooling

Using energy-saving equipment for a greener center

Tip: Operators who use a pdu power calculator can stop overloads and keep the data center working well.

Planning for more growth is simple with a pdu power calculator. Operators pick PDUs with extra outlets and modular designs. This lets them add new servers fast. They balance power and use two power feeds for better reliability. Operators choose intelligent PDUs with real-time monitoring and remote control. These features help teams manage power as the center grows. Safety certifications like UL and CE make sure rules are followed. Operators also check the site to match PDU size with rack power needs.

Steps for planning growth with a pdu power calculator:

Make sure it works with current hardware and systems.

Put remote monitoring and control first.

Pick vendors that are reliable and give good support.

Plan regular maintenance for long-term use.

Use outlet-level control for better power management.

Operators who plan ahead with a pdu power calculator can grow easily, keep uptime high, and support new tech.

Good PDU power management helps data centers work better and last longer. Operators use intelligent PDUs to watch power in real time and control things from far away. Modular designs make it easy to change setups. YOSUN’s High Power PDU can be customized. It has strong surge protection and sensors for the environment.

Reliable power and balanced loads help stop outages.

Remote control and outlet-level management keep systems running.

Custom PDUs make it easy to grow and save energy.

Data centers that improve power management have less downtime, save more energy, and do well for a long time.

Intelligent PDUs let operators see data right away and control things from far away. These features help teams stop downtime, use less energy, and handle power better.

YOSUN’s High Power PDU has locking outlets and strong circuit breakers. These features stop plugs from coming out by mistake and keep equipment safe from too much power.

Operators talk with YOSUN’s engineers to pick how to mount, what outlets to use, and which power connections are best. This makes sure each PDU fits what the data center needs.

Three-phase power gives more power and uses smaller cables. Operators use it to make setup easier, save money, and give steady power to racks with lots of equipment.

Experts say teams should update firmware often. Updates add new security, make things work better, and help PDUs work with the newest tools.

A Professional And Leading Manufacturer

For OEM

& ODM Power Distribution Unit (PDU)

You Can Trust

CONTACT

Ningbo YOSUN Electric Technology Co., LTD

Leading Professional Manufacturer in PDU Power Solutions

Contact Info.