© Copyright – 2010-2023 : All Rights Reserved. Sitemap

Power Distribution Unit PDU, rack mount PDU, PDU data center, Smart PDu, intelligent PDU

Power Distribution Unit PDU, rack mount PDU, PDU data center, Smart PDu, intelligent PDU

Global Sources Consumer Electronics, DATE:Apr 11-14th, 2025, Booth No.: 9H09

PDU power strip

PDU power strips, or Power Distribution Units, are advanced electrical devices designed primarily for managing power distribution in environments such as data centers and server rooms. They serve a similar purpose to standard power strips but offer enhanced functionality and features tailored for more complex power needs.

YOSUN can provide basic pdu power strip and intelligent pdu power strip. Basic PDUs provide additional outlets but no power usage data. Metered PDUs give you real-time data but no way to remotely access or aggregate the data. Monitored PDUs provide essential real-time and historical information allowing you to analyze trends and alert personnel to impending problems. Switched PDUs provide the capabilities of monitored PDUs with the additional benefit of remote on/off power control at the outlet level.

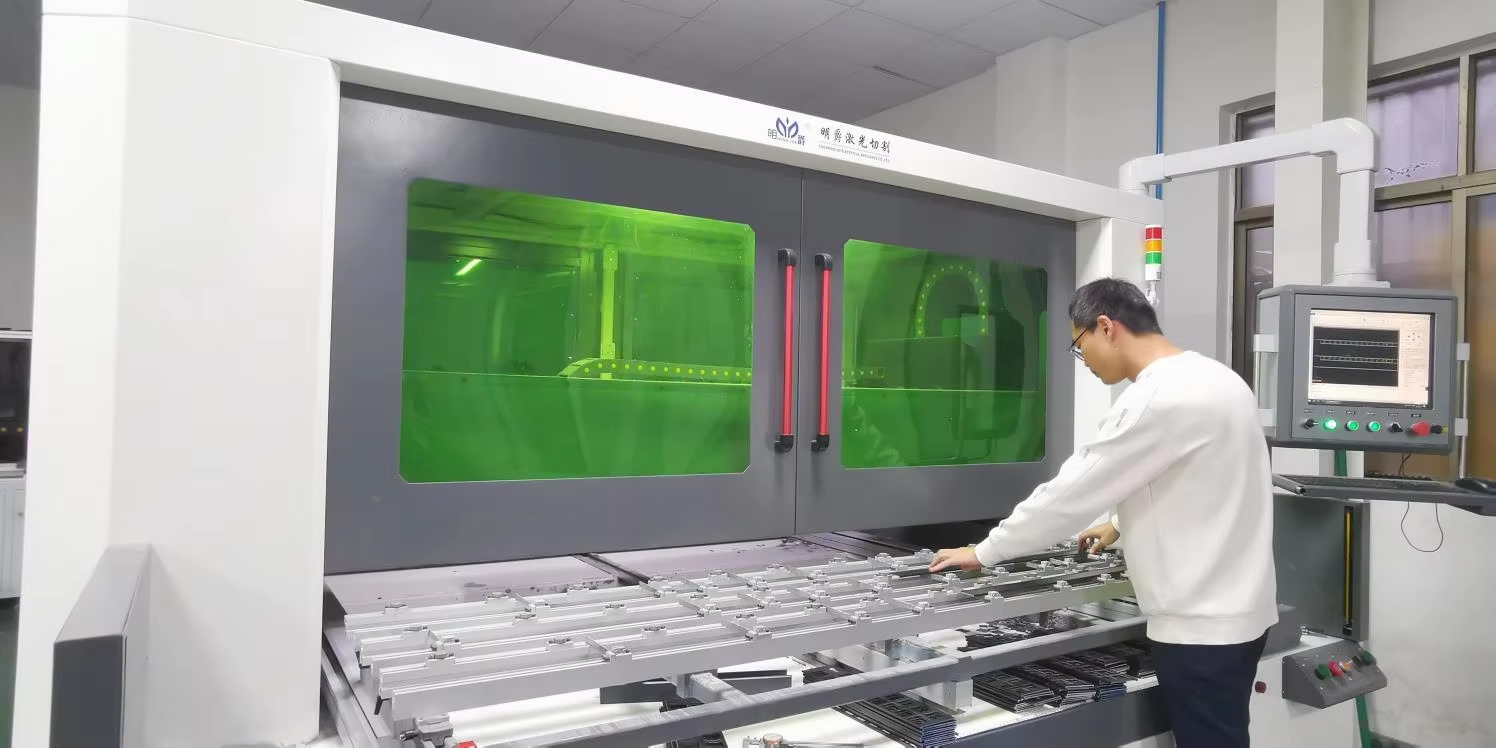

YOSUN allows users to create personalized solutions tailored specifically for their needs. Our specialized teams in engineering, reliability, compliance, and sales offer customers the opportunity to engage directly in the design and production of customized server rack power strip configurations that fulfill their specific requirements.The following are the customization options YOSUN can provide you:

Customers can select the number of outlets for the rack PDU according to their needs, with options available for 8, 12, 24, 30, or even more outlets.

Various receptacle types for the rack PDU can be chosen based on the equipment requirements of the customer. Options include NEMA, IEC 60320 – C13 and C19, Schuko sockets, French sockets, and others.

Customers have the flexibility to choose different mounting orientations for the rack PDU, including vertical or horizontal installation.

The rack PDU can be tailored to meet specific voltage and current specifications as per customer requirements, with options such as 125V, 250V, 15A, 16A, 20A, and more.

Rack PDUs come in various modular designs, enabling customers to customize their power distribution solutions according to their particular needs.

Customers can select from a range of safety protection features for the rack PDU, including surge protection, overload protection, short circuit protection, and additional options.

The monitoring and control capabilities of the rack PDU can be customized based on specific application scenarios. This includes remote monitoring and control via protocols such as SNMP and HTTP, along with alarm notification support.

Customers can choose from different enclosure materials for the rack PDU, including metal or industrial-grade plastic.

The design of the rack PDU can be customized to meet customer preferences in terms of color, size, labeling, and more.

Additional custom requirements for the rack PDU can also be accommodated, such as special wiring configurations and custom labeling options.

Quality control strictly according to ISO9001. Quality has always been paramount at YOSUN. Our PDU have Qualifed to GS, CE, VDE, ULBS, CB, ROHS,CCC certifications, assuring customers that the products they receive are safe, reliable, and made of the highest quality.

PDU (Power Distribution Unit) and power strip are both devices used to distribute power, but they differ in several key ways:

Outlets and Power Capacity

– PDUs typically have more outlets (8-40+) than power strips (2-20) and can support higher amperages

– PDUs offer a variety of outlet types to support different equipment, while power strips usually have standard NEMA 5-15R outlets

Mounting and Cord Length

– PDUs are designed for rack mounting, either horizontally or vertically, while power strips are meant to lie on the floor or a shelf

– PDU power cords are limited to 15 feet due to the higher load, while power strip cords can be up to 25 feet

Advanced Features

– PDUs often include features like remote switching, outlet-level monitoring, and alerting capabilities, which power strips lack

– PDUs have circuit breakers to protect the branch circuit wiring, while power strips rely on a single switch

Applications

– PDUs are better suited for data centers, server rooms, and professional environments requiring advanced power management

– Power strips are more suitable for basic power extension needs in homes, small offices, or less critical applications

Overcurrent Protection: Look for PDU power strips equipped with a built-in circuit breaker that automatically shuts off the power when the current exceeds safe limits. This feature helps prevent overheating and potential fire hazards.

Surge Protection: A surge protector is essential, especially in environments prone to electrical fluctuations. It safeguards connected devices from voltage spikes, which can be particularly damaging during storms or when heavy machinery is in use.

Heat-Resistant Materials: Ensure that the power strip is constructed from materials that can withstand high temperatures. Some models are made from fireproof materials that can endure temperatures up to 1500°F without burning.

Weatherproof and Shockproof Design: If the PDU power strip will be used outdoors or in humid environments, it should have an IP rating (like IPX6) indicating it is waterproof and resistant to moisture. Additionally, shockproof designs help prevent electric shocks, especially in settings where children or pets may be present.

UL Certification: Always check for UL (Underwriters Laboratories) certification, which indicates that the product meets safety standards for electrical devices. This certification can help ensure reliability and safety in high-temperature applications.

Ventilation Features: PDU power strips should allow for adequate airflow around them to prevent overheating. Models designed with ventilation slots can help dissipate heat more effectively.

Limited Load Capacity: Choose a power strip that specifies a maximum load capacity appropriate for your devices. Avoid overloading by ensuring the total wattage of connected devices does not exceed this limit.

1. Choose Quality Equipment

Select high-quality power strip PDUs that are UL-listed or certified by reputable organizations. These devices are designed to handle electrical loads safely and efficiently. YOSUN’s cabinet pdu power strip is your best choice.

2. Avoid Overloading

Be mindful of the total wattage of all devices plugged into the power strip. Do not exceed 70% of the power strip’s rated capacity. For example, if using a 15A circuit, limit the load to about 1250 watts.

3. Proper Ventilation

Ensure that the power strip has adequate airflow around it. Avoid placing it in enclosed spaces without ventilation. While some sources suggest that power strips do not require ventilation, keeping them cool can help prevent heat buildup.

4. Regular Inspections

Periodically check the rack moun power strip for signs of wear, such as discoloration or melting plastic, which can indicate overheating issues. Replace any damaged units immediately.

5. Use Circuit Breakers

Ensure that your power strip or PDU has an internal circuit breaker that will trip in case of overload, providing an additional layer of safety against overheating.

6. Avoid Daisy Chaining

Do not connect multiple power strips together (daisy chaining), as this significantly increases the risk of overloading and overheating.

A Professional And Leading Manufacturer

For OEM

& ODM Power Distribution Unit (PDU)

You Can Trust

CONTACT

Ningbo YOSUN Electric Technology Co., LTD

Leading Professional Manufacturer in PDU Power Solutions

Contact Info.