© Copyright – 2010-2023 : All Rights Reserved. Sitemap

Power Distribution Unit PDU, rack mount PDU, PDU data center, Smart PDu, intelligent PDU

Power Distribution Unit PDU, rack mount PDU, PDU data center, Smart PDu, intelligent PDU

DTI-CX 2025 Digital Transformation Indonesia Conference, DATE:6-7 AUG.2025, Booth No.: C21

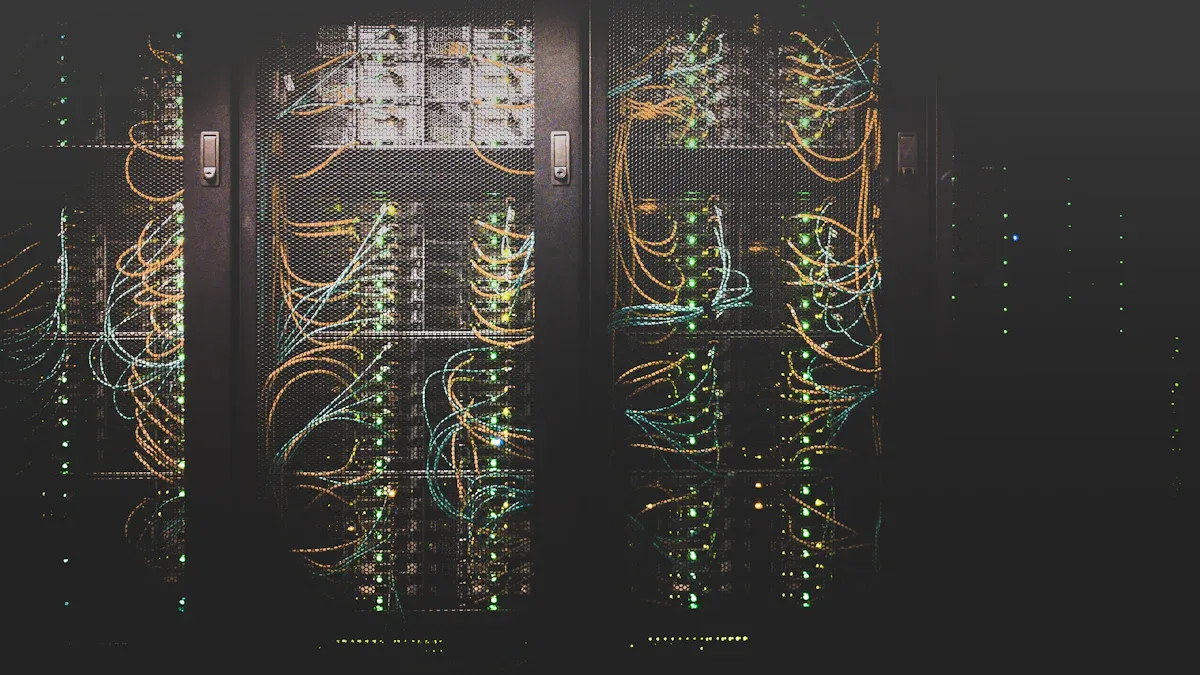

The modern power distribution unit evolves to meet intense demands. Workloads from artificial intelligence (AI) and high-performance computing drive this change, and the power needs for these systems are substantial. Whether you deploy a basic PDU, a smart PDU, or a fully intelligent PDU, each plays a role in supporting these rising requirements.

AI workloads consume nearly four times the power of traditional systems. Data center capacity for AI is expected to grow at a 33% annual rate through 2030.

An advanced electrical PDU now features outlet-level remote control and real-time power monitoring, and the market for intelligent management is expanding rapidly.

| Metric | Value |

|---|---|

| Global Market Size (2024) | USD 1.46 billion |

| Projected Market Size (2033) | USD 2.99 billion |

| Compound Annual Growth Rate (2025-2033) | 7.8% |

The future power distribution unit also integrates cybersecurity protocols and environmental sensors to protect critical hardware. Designs include hot-swappable components for maximum uptime.

The evolution of IT equipment outpaces the typical lifecycle of a data center. This creates a pressing need for advanced power infrastructure. By 2025, a power distribution unit must deliver significantly more power within the same physical footprint to support next-generation technologies.

Artificial intelligence (AI) and high-performance computing (HPC) are the primary drivers of higher rack densities. These compute-intensive applications reshape the modern data center, demanding larger and more flexible power solutions. The power consumption of individual components has grown exponentially.

| Component | Power Consumption |

|---|---|

| GPUs for AI (Until 2022) | 400 watts |

| GPUs for Gen AI (2023) | 700 watts |

| Next-Gen Chips (2024) | 1,200 watts (expected) |

Facility designs now regularly accommodate high-density racks drawing 15-30 kW, a significant jump from the previous 5-10 kW standard. To meet these needs, high capacity pdus increasingly utilize three-phase power. This approach delivers more power efficiently with smaller wiring, simplifying installation

Note: Increased power density directly leads to higher operating temperatures inside the server rack. A PDU’s ability to perform reliably in a hotter environment is now a critical design requirement.

A high density pdu is engineered to withstand elevated ambient temperatures. As servers and accelerators consume more energy, they also generate more heat, raising the baseline temperature of the rack environment. An advanced power distribution unit incorporates energy-efficient components, such as bi-stable relays. These components reduce the PDU’s internal power consumption and heat output, contributing to a more stable operating environment and lowering overall energy costs. This resilience ensures that power delivery remains consistent even as the thermal load inside the rack increases.

Power system failures cause nearly half of all significant data center outages. This makes intelligent oversight essential for modern operations. An advanced power distribution unit in 2025 moves beyond simple power delivery. It becomes a central hub for automation and remote monitoring, providing robust power management solutions that prevent downtime before it occurs.

Data center managers require precise control over every device in the rack. A switched pdu provides this capability. It allows administrators to remotely power cycle individual outlets to reboot unresponsive IT equipment. This function eliminates the need for costly on-site service calls. Key remote actions include:

This level of control is also vital for effective energy management. Administrators can schedule shutdowns for idle equipment, significantly reducing energy waste. For example, a metered outlet pdu provides the data needed to identify these opportunities, helping to optimize Power Usage Effectiveness (PUE) and lower operational costs.

The most advanced power distribution unit uses data to predict and prevent failures. Integrated analytics platforms monitor power consumption in real time. They can identify dangerous trends before they lead to an outage.

Tip: Predictive analytics can detect subtle anomalies that often precede a major failure, such as abnormal power usage patterns, circuit overloading, and gradual overheating.

This intelligent load management is a cornerstone of data center reliability. The power distribution unit collects and analyzes data, sending alerts when user-defined thresholds are breached. This information often integrates directly with Data Center Infrastructure Management (DCIM) software. This integration gives operators a complete view of power consumption and environmental conditions, turning raw data into actionable insights for capacity planning and efficiency improvements.

A modern power distribution unit extends its role beyond power delivery. It becomes a critical guardian of both digital and physical assets. Integrated security and environmental monitoring are now essential features for protecting the data center environment.

As PDUs become more connected, they also become potential targets for cyberattacks. The convergence of IT and operational technology (OT) exposes power infrastructure to new risks. Malicious actors can disrupt operations by targeting these connected devices.

Common threats include:

To counter these threats, an advanced power distribution unit incorporates robust security protocols. Secure network management protocols like SNMPv3 are standard. They provide essential protections that older versions lack.

| Threat | SNMPv3 Protection |

|---|---|

| Masquerade | Verifies message origin with data integrity checks. |

| Modification | Prevents alteration of in-transit messages. |

| Disclosure | Stops eavesdropping through strong encryption. |

| Unauthorized Access | Controls operator actions with an access control table. |

Furthermore, compliance with standards like IEC 62443, an industrial cybersecurity framework, ensures that the device’s entire lifecycle is secure. Role-based access control (RBAC) adds another layer of defense. It allows administrators to grant specific permissions based on a user’s role, such as limiting access to certain racks or subnets.

Physical conditions inside the rack are just as important as cybersecurity. Excessive heat or humidity can cause hardware failure and costly downtime. A smart power distribution unit uses built-in sensors to monitor the rack-level environment in real time. These sensors track temperature, humidity, and airflow, providing immediate alerts when conditions deviate from safe operating ranges.

This proactive monitoring helps maintain optimal conditions as defined by industry standards like ASHRAE.

| Equipment Class | Recommended Temperature (°C) | Allowable Relative Humidity (%) |

|---|---|---|

| A1 | 18-27 | 8-80 |

| A4 | 5-45 | 8-90 |

When a sensor detects a problem, such as a failing server fan causing a temperature spike, the PDU sends an alert via email, SMS, or SNMP trap. This allows data center operators to address the issue before it leads to equipment damage, ensuring hardware longevity and uninterrupted service.

In a data center, uptime is everything. The reliability of an electrical pdu is therefore non-negotiable. By 2025, advanced designs will focus on eliminating single points of failure through built-in redundancy and modular components, ensuring continuous operation for critical IT infrastructure.

A modern power distribution unit provides robust protection against power interruptions. It achieves this with dual power inputs and an integrated Automatic Transfer Switch (ATS). This design ensures a seamless transition to a secondary power source if the primary one fails.

An ATS power distribution unit contains key components like dual power interfaces, sensors, a transfer switch, and control logic. This system intelligently monitors power and triggers a switch in milliseconds, often between 10 to 16 milliseconds, preventing any disruption to connected equipment.

This fail-safe mechanism offers a dramatic improvement in reliability. Data centers with single-source power can face up to 28 hours of downtime annually. Implementing a redundant power distribution unit with automatic switching cuts this risk to less than two hours per year, safeguarding business continuity.

Maintenance and component failure are significant sources of downtime. An advanced electrical pdu addresses this challenge with a modular, hot-swappable design. This allows technicians to replace key modules, such as the main controller, without powering down the entire strip or affecting connected servers. This capability is crucial for addressing common failure points, which include:

Hot-swappable components simplify repairs and upgrades, reducing the Mean Time to Repair (MTTR). Instead of scheduling a major maintenance window, operators can quickly swap a faulty part, minimizing operational risk and ensuring the power infrastructure remains resilient and easy to manage.

An advanced electrical pdu in 2025 combines high-power capacity, intelligent automation, and integrated security. These features are now essential for any modern data center. The market’s growth, projected to reach USD 3.40 billion in 2025, confirms this trend. Operators should assess their current power infrastructure to plan for necessary upgrades.

Assessment Checklist:

This review prepares your electrical pdu and power systems for future demands.

AI and HPC workloads consume immense energy. A high-power PDU delivers over 20kW to support these dense server racks. This capacity prevents overloads and ensures stable operation for critical, next-generation computing tasks.

A smart PDU offers remote control and monitoring for each outlet. Administrators can reboot devices, schedule shutdowns, and track energy use. This intelligence helps optimize power consumption and manage the data center infrastructure efficiently.

Advanced PDUs use dual power inputs and an Automatic Transfer Switch (ATS). If one power source fails, the ATS instantly switches to the backup source. This fail-safe design ensures continuous power for connected equipment.

Yes, manufacturers can provide custom power solutions. PDUs are designed for specific applications like data centers or edge computing. They offer various outlet types, such as IEC, Schuko, or American, to meet global market requirements.

A Professional And Leading Manufacturer

For OEM

& ODM Power Distribution Unit (PDU)

You Can Trust

CONTACT

Ningbo YOSUN Electric Technology Co., LTD

Leading Professional Manufacturer in PDU Power Solutions

Contact Info.